Common Materials Used in Electronic Components

Electronic components are the building blocks of modern technology, powering everything from smartphones to industrial machinery. These components rely on a variety of materials, each chosen for its specific electrical, mechanical, or thermal properties. Understanding the materials used in electronic components is key to grasping how these devices function and how they are produced. Below are some of the most common materials found in electronic components and their roles in ensuring the functionality of electronic systems.

1. Semiconductors: Silicon and Germanium

Semiconductors are at the heart of most electronic devices, and silicon is the most widely used material in the manufacturing of semiconductor components like diodes, transistors, and integrated circuits (ICs). Silicon's ability to control electrical conductivity makes it ideal for these applications. It can act as both a conductor and an insulator depending on how it is doped with other elements, allowing for precise control of electric currents in devices.

Germanium, another semiconductor material, was used in earlier electronic components but has largely been replaced by silicon due to its superior properties and availability. However, germanium is still used in some high-speed devices and specialized applications like optical fiber communication systems.

2. Conductors: Copper and Aluminum

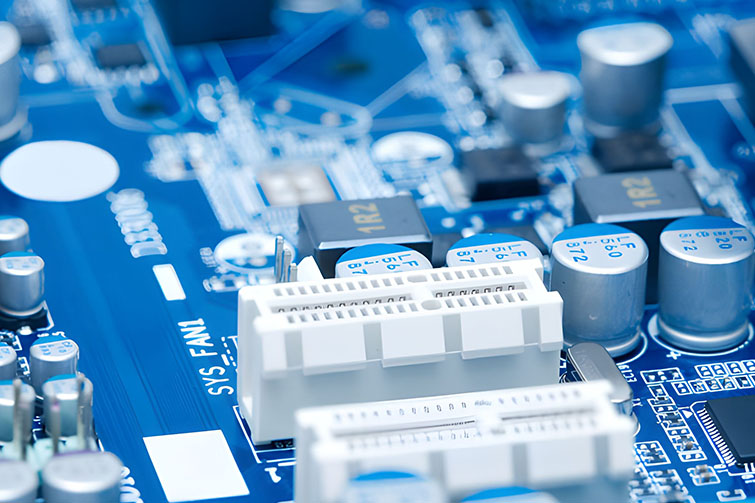

Conductive materials are essential in the creation of circuits, as they enable the flow of electricity from one component to another. Copper is the most commonly used conductor in electronic components due to its excellent electrical conductivity and malleability. It is widely used in wiring, printed circuit boards (PCBs), and various electronic connectors.

Aluminum is also used as a conductor in some applications, particularly where weight and cost are concerns. While it is not as conductive as copper, aluminum is lighter and more affordable, making it a good option for larger power transmission systems and in cases where the weight of components is a factor.

3. Insulators: Plastic and Ceramics

Insulating materials are crucial in electronic components to prevent unintended current flow and ensure that electricity is directed where it is needed. Plastics, such as polyvinyl chloride (PVC) and polyethylene, are commonly used as insulators for wires and cables because they are flexible, durable, and inexpensive.

Ceramics, such as aluminum oxide (Al2O3), are another key insulating material, often found in capacitors, resistors, and other components that require strong electrical insulation at high temperatures. Ceramics also provide mechanical strength and thermal stability, making them suitable for use in environments with extreme conditions.

4. Capacitive Materials: Tantalum and Ceramic

Capacitors are electronic components that store and release electrical energy. The materials used in capacitors depend on their intended application. Tantalum is a commonly used material in electrolytic capacitors, valued for its high capacitance and ability to operate at small sizes. Tantalum capacitors are commonly found in compact devices like smartphones and laptops.

Ceramic materials, specifically barium titanate, are widely used in ceramic capacitors, which are known for their stability, high voltage resistance, and affordability. Ceramic capacitors are used in a variety of applications, from power supply filtering to signal coupling and decoupling in electronic circuits.

5. Magnetic Materials: Ferrite and Iron

Magnetic materials are used in inductors, transformers, and other components that rely on magnetic fields to function. Ferrite, a type of ceramic material made from iron oxide mixed with other elements, is commonly used in the cores of transformers and inductors. Ferrite materials help enhance the inductance of coils and improve the efficiency of power conversion in electronic circuits.

Iron and its alloys are also used in magnetic components, especially in power transformers and motors, where strong magnetic properties are required to handle high currents and voltages.

6. Resistor Materials: Carbon and Metal Film

Resistors control the flow of electrical current in a circuit by providing resistance. Carbon is one of the most commonly used materials in resistors, especially in carbon-composition and carbon-film resistors. These types of resistors are often used in general-purpose electronic devices due to their low cost and ease of production.

Metal film resistors, which use materials such as nickel-chromium (NiCr) or tin oxide, offer more precise resistance values and are used in high-precision applications. Metal film resistors are also known for their stability over time and their ability to handle high frequencies.

7. Soldering Materials: Tin-Lead and Lead-Free Alloys

Solder is used to join electronic components to PCBs, creating a reliable electrical connection. Traditionally, solder was made from a mixture of tin and lead, as this combination offers a low melting point and good electrical conductivity. However, due to concerns about lead toxicity, lead-free solder alloys are now commonly used in electronic assembly.

Lead-free solders typically contain a mixture of tin, copper, and silver, and while they require higher temperatures to melt, they provide a more environmentally friendly solution for modern electronics manufacturing.

8. Substrates: Fiberglass and Epoxy

PCBs, which house and connect electronic components, are typically made from rigid substrates that provide mechanical support and insulation. Fiberglass, combined with epoxy resin, is the most common material used for PCBs. This combination, known as FR4, offers excellent thermal stability, durability, and insulation, making it ideal for a wide range of electronic applications.

In flexible electronics, polyimide is often used as a substrate material, offering flexibility and heat resistance for components that need to bend or fold.

Conclusion

The materials used in electronic components are carefully selected based on their electrical, mechanical, and thermal properties. From semiconductors like silicon and germanium to conductive materials like copper and insulating materials like plastic and ceramics, each material plays a specific role in ensuring that electronic devices function as intended. As technology advances, the demand for new and innovative materials will continue to grow, driving further developments in the field of electronic component manufacturing.